Product Search

Solution Search

Searchable by product name, product model or standard.

When searching by product model, enter the product model excluding the option code (-FA, -L, -NEXT, etc.).

*To search by solution, switch to “solution search.”

i.e., Load Cells, ZTA-50N, 7864 (for ISO 7864)

Searchable by you force type, industry, standard or product sample.

*To search by product, switch to “product search.”

i.e., Compression, 7864 (for ISO 7864)

SEARCH

Daily Inspection

Daily Inspection

- Force Measurement IMADA

- SERVICE & SUPPORT

- Daily Inspection

Daily inspection of force gauges

For long-term use of force gauges, IMADA recommends daily inspection of force gauges.

1. Check the displayed value

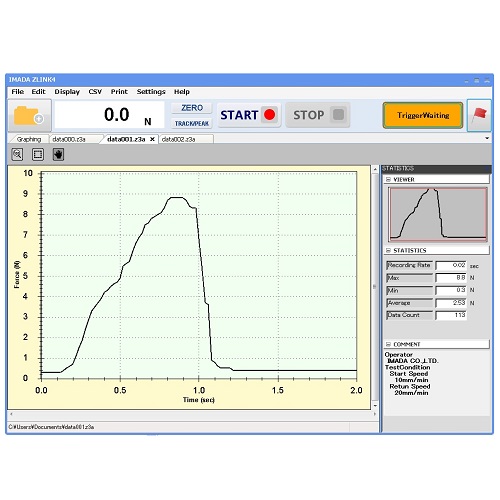

For all measuring instruments, including force gauges, accurate display value is essential. The accuracy of the display values is confirmed by comparing the relationship between the display value of the standard instrument and the value of the measuring instrument, and this is called the calibration procedure. Regular calibration and accuracy adjustment is essential to maintain the measurement accuracy of the instrument.

A force gauge calibration checks whether the measuring instrument's displayed value is within the tolerance range when a constant load is applied accurately. However, accurately applying constant load is complex and requires sophisticated tasks and investment in equipment installation. Therefore, it is not easy to set up a calibration system individually, and in most cases, the manufacturers of the measuring instruments or the specialized calibration organizations perform the calibration. About IMADA’s Calibration Service>

Regular periodical full-scale calibration by the calibration specialists is essential. Additionally, there are means to perform basic calibration in-house. This helps users detect issues and irregularities immediately and positively affects risk management, such as quality control. IMADA recommends the following 2 in-house calibrations: A) Calibration with the Tabletop Calibration Unit, B) Calibration with a Calibration Stand

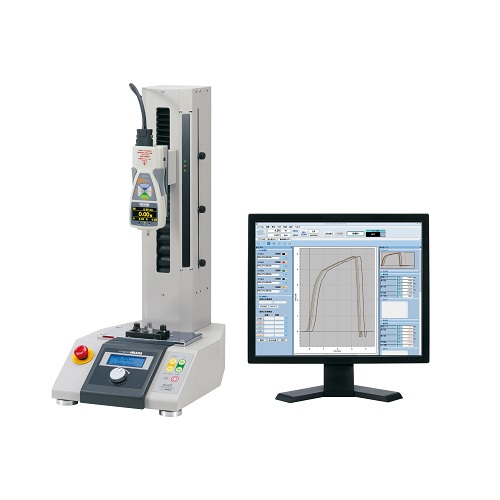

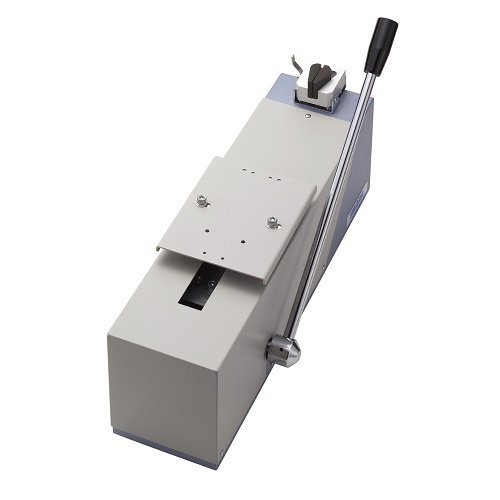

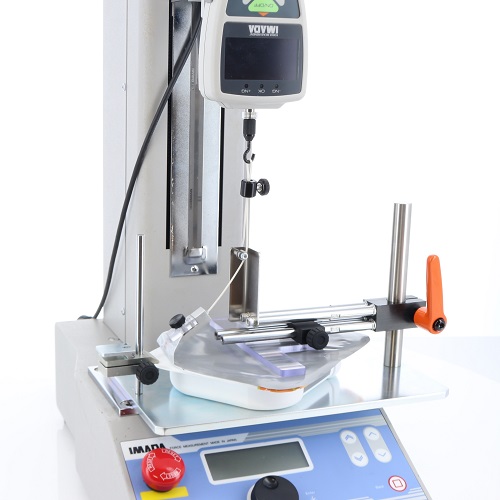

A) Calibration method using the Tabletop Force Gauge Calibration Unit

The method with IMADA's Tabletop Force Gauge Calibration Unit TFCU series and a force gauge with reliable accuracy is used as a standard to compare the force gauge value to be calibrated. The measuring shafts of two force gauges are pressed against or pulled to check for noticeable measurement value differences. Calculation based on the value displayed and the specification accuracy enables the understanding of the current accuracy range of the measuring instrument. Additionally, recording the daily calibration results helps to locate the noticeable change in the measurement values, which helps with early problem detection.

- Less expensive and space-saving compared to calibration methods using a calibration stand and weights

- Easy to operate, and no special training is required

- Periodic calibration service for standard force gauges is also provided by IMADA

Free 6-page PDF document available with “the in-house calibration procedures with TFCU Series”, “Additional daily inspection hints”, and “Points to help avoid failures and malfunctions”. Please request from the link below: -

Request Docs[Tensile calibration of force gauges using the Tabletop Force Gauge Calibration Unit]

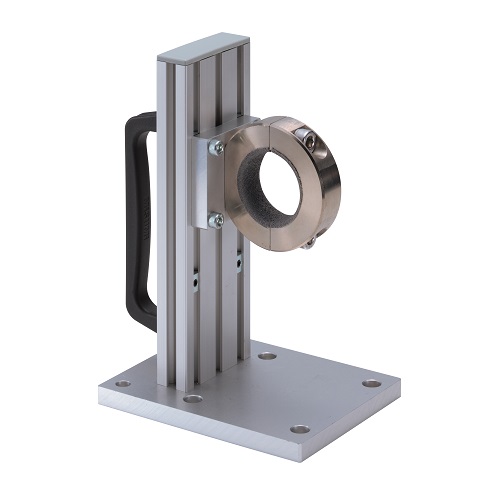

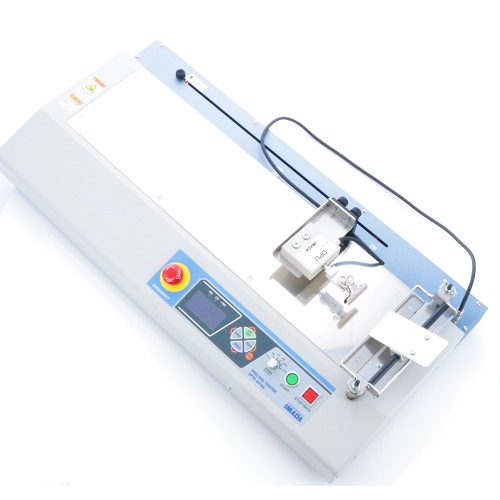

B) Calibration method using a Calibration Stand, Calibration Plates, and Weights

For this method, a force gauge is mounted on a calibration stand. The method involves hanging a calibration plate to the measuring shaft of the force gauge, and weights are added to check the values on the display. The calibration stand / calibration plates are made-to-order by IMADA, and it would be possible to practice with specialized in-house calibration, as shown in the video, for your information. *The standard weights are not available from IMADA.

2. Confirm Basic Operation and Appearance

The following items, other than the display values, are recommended for daily inspection.

- External appearance check: No unnatural dents or damage, no signs of tilt or distortion of and around the measuring shaft, etc.

- Basic operation check: screen display, response to button operations, etc.

Suppose any unusual signs or irregularities are identified, our advice is to stop using the measuring instrument immediately for safety and request repairment. For more information about daily inspection of force gauges, please request a document from the button below. Free 6-page PDF document available with “Daily inspection hints”, “the in-house calibration procedures with TFCU Series”, and “Points to help avoid failures and malfunctions”. *The document is the same as the one mentioned in point 1.

3. Storage

Please take note of the following points, especially if the product will not be used for an extended period:

- Store in the provided case: This is to prevent the sensor from being overloaded due to accidental drops or unintended contact.

- Keep in a location free from significant vibrations: For the same reasons as mentioned above.

- Temperature: 0-40℃, Humidity: 20-80% RH in a non-condensing environment: Adhering to these storage conditions will minimize the risk of malfunction.

Risks and Measures for Long-Term Inactivity:

- For digital products, there is a risk of not being able to use them due to over-discharge. To prevent this, please charge them periodically.

- We recommend calibration every year. Especially if the product has been stored without use for over a year, we strongly recommend sending it for calibration before use.

*Please note that the above precautions do not guarantee that the product will not malfunction.

Contact us

If you find any abnormability, or have any questions, please feel free to contact us.

Contact usConverter

Convenient Unit/Torque/

Tension conversion

6 Significant Digits (*Significant digits are meaningful digits that do not include zeros, which are used to indicate the scale.)

Products

HERE!

Attachments, Grips & Fixtures

Attachments, Grips & Fixtures

Software / Download Card

Software / Download Card

Additional Chargeable Function for Software

Additional Chargeable Function for Software

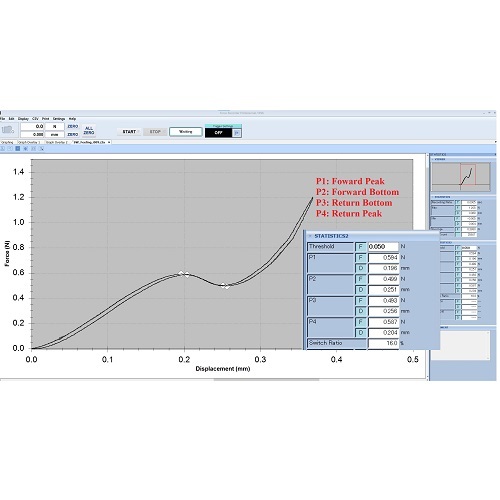

Friction Testing Module

Friction Testing Module

Peel Testing Module 1

Peel Testing Module 1

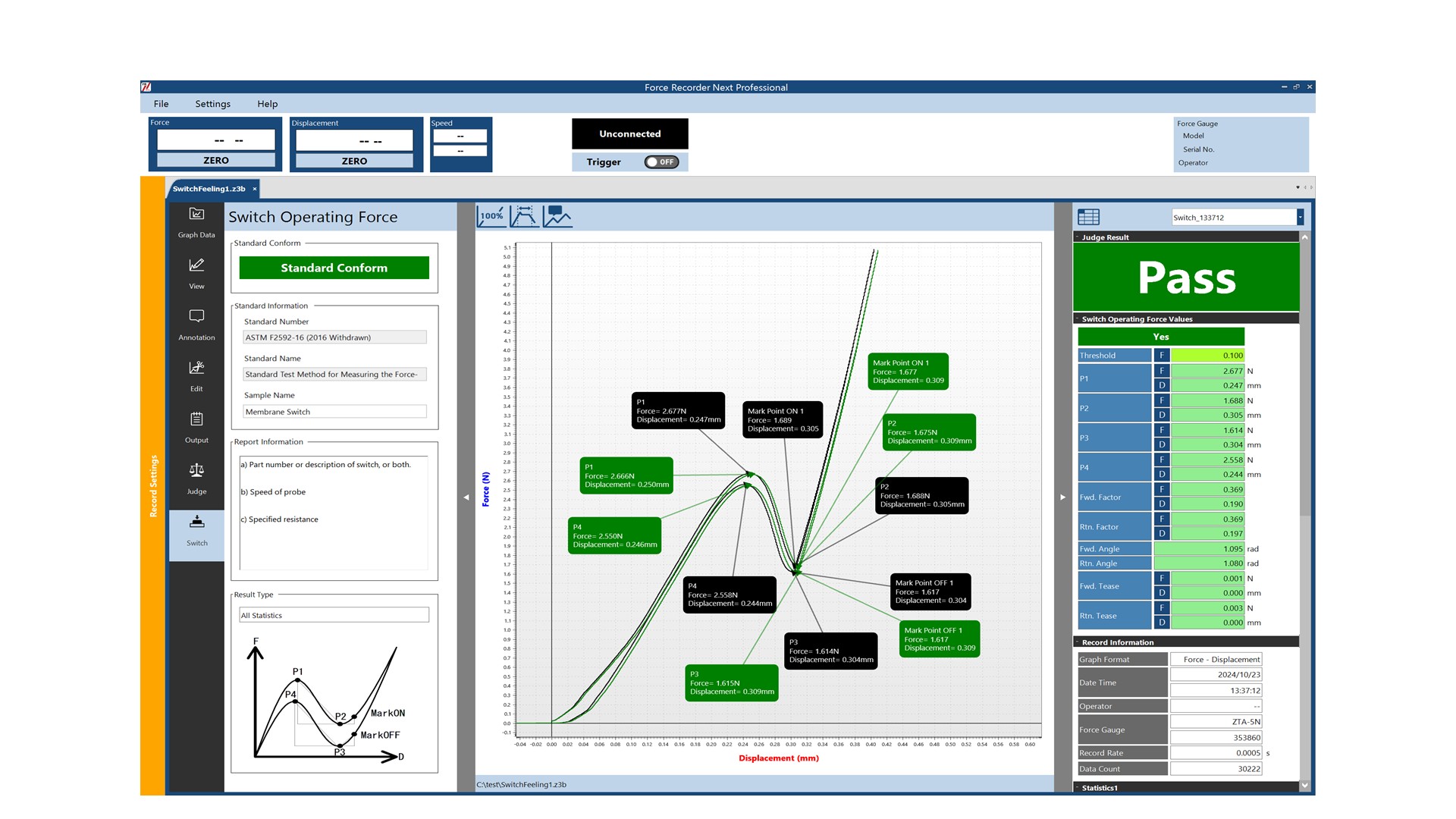

Switch Operating Force Testing Module

Switch Operating Force Testing Module

Pressure/Stretchability Measurement Module

Pressure/Stretchability Measurement Module

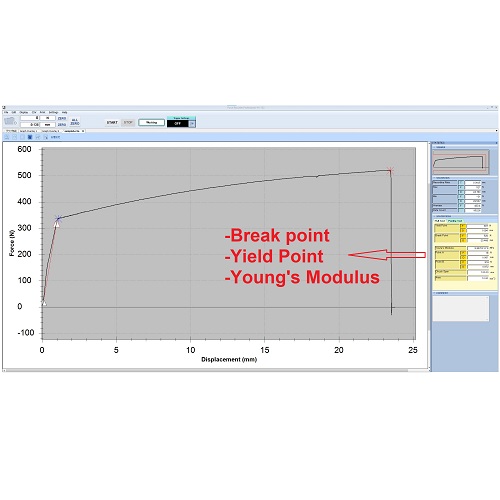

Spring Rate Measurement Module

Spring Rate Measurement Module

Deflection Correction Function

Deflection Correction Function

Bending Stress Measurement Module

Bending Stress Measurement Module

Excel Data Writing Function

Excel Data Writing Function

Yarn Tenacity Testing Module

Yarn Tenacity Testing Module

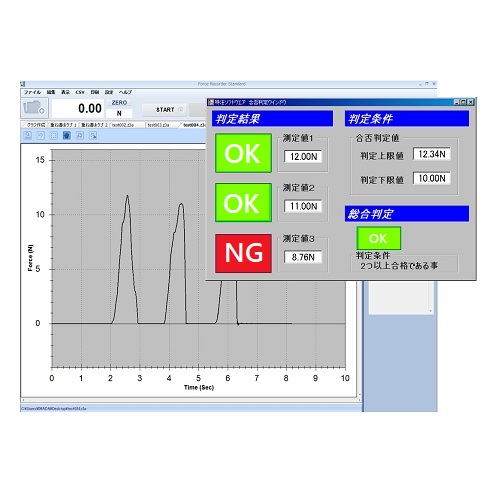

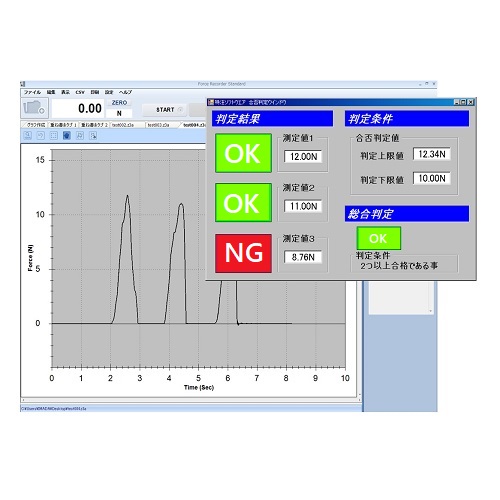

Multi-Peak Extraction Function

Multi-Peak Extraction Function

Multi-Level Evaluation Function

Multi-Level Evaluation Function

Custom Made

Custom Made

Measurements in Special Environment

Measurements in Special Environment

Temperature and Angle Adjustable Peel Tester

Temperature and Angle Adjustable Peel Tester

Spot Welding Pressure Gauge

Spot Welding Pressure Gauge

Attachment to Bend Sample 90 Degrees

Attachment to Bend Sample 90 Degrees

Horizontal Test Stand with Fine Adjustment Knob

Horizontal Test Stand with Fine Adjustment Knob

Tester With Thermostatic Chamber

Tester With Thermostatic Chamber

Tester With Far-infrared Heater

Tester With Far-infrared Heater

Table for Compression Load Cell

Table for Compression Load Cell

Test Stand for Testing at the Desired Position

Test Stand for Testing at the Desired Position

Particular Samples Measurements

Particular Samples Measurements

Peel Test Fixture for Crimped Postcard

Peel Test Fixture for Crimped Postcard

Attachment for Fixing Wide and Thin Materials

Attachment for Fixing Wide and Thin Materials

Attachment for Wine Cork Extraction Test

Attachment for Wine Cork Extraction Test

Attachments for 90 degree score bend test

Attachments for 90 degree score bend test

Attachments to measure forces to open flat pack carton

Attachments to measure forces to open flat pack carton

Attachments for break strength testing of lipsticks or lip balms

Attachments for break strength testing of lipsticks or lip balms

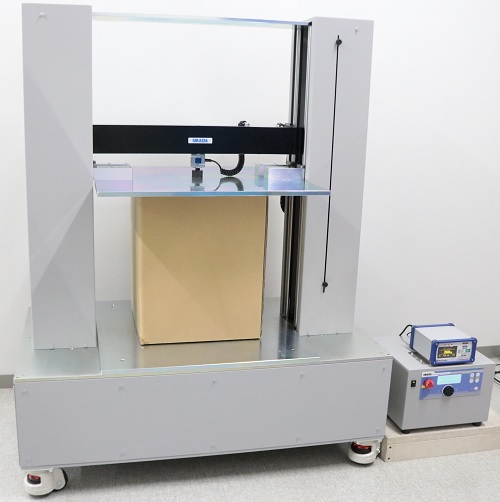

High capacity dual-column motorized test machine for compression test

High capacity dual-column motorized test machine for compression test

Film Grip with Openable Gripping Part

Film Grip with Openable Gripping Part

Pantograph Grip with Pressurization Mechanism

Pantograph Grip with Pressurization Mechanism

Motorcycle Accelerator Torque Test Fixture

Motorcycle Accelerator Torque Test Fixture

Peel Test Fixture for Solar Cell Ribbon

Peel Test Fixture for Solar Cell Ribbon

Test Stand With Large Table

Test Stand With Large Table

Compression Test Attachment for LCD Panel

Compression Test Attachment for LCD Panel

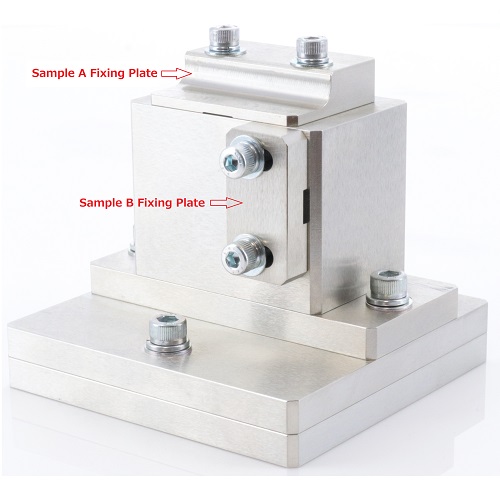

L-shaped Sample Fixture

L-shaped Sample Fixture

Attachment for Opening/Closing Force Test of Takeout Container Lid

Attachment for Opening/Closing Force Test of Takeout Container Lid

Attachment for Squeezing Force Test of Eye Drop Bottles

Attachment for Squeezing Force Test of Eye Drop Bottles

Compression Test Attachment for Squeeze Tube

Compression Test Attachment for Squeeze Tube

Attachment for Welded Nut Tension Test

Attachment for Welded Nut Tension Test

Attachment for Tube Tension Strength Test

Attachment for Tube Tension Strength Test

Attachment for Hard-to-Grip Samples

Attachment for Hard-to-Grip Samples

Attachment for Compression Test of Nasal Spray

Attachment for Compression Test of Nasal Spray

Individually Adjustable Torque Chuck Attachment

Individually Adjustable Torque Chuck Attachment

Resistance Force Measurement jig for Hair Combing Test

Resistance Force Measurement jig for Hair Combing Test

Attachment for Lateral Compression Test of Cup Containers

Attachment for Lateral Compression Test of Cup Containers

Water-Proof Shield for Motorized Torque Test Stand

Water-Proof Shield for Motorized Torque Test Stand

Biaxial Tension Tester

Biaxial Tension Tester

Resize & Modification

Resize & Modification

Press Test Fixture (Wide Size)

Press Test Fixture (Wide Size)

Remote Control Switch for Motorized Test Stand

Remote Control Switch for Motorized Test Stand

Semi-Customized Compression Attachments

Semi-Customized Compression Attachments

Large Size of Compression Tester

Large Size of Compression Tester

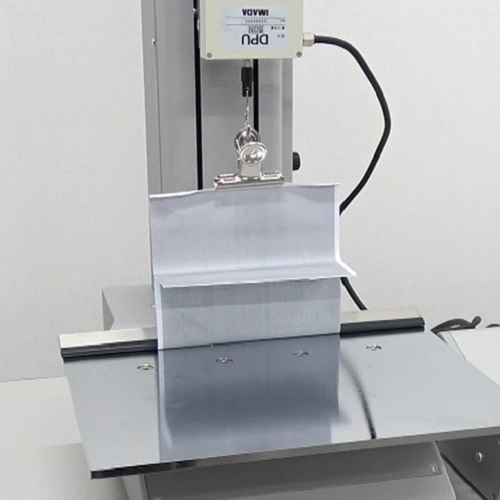

Large Size of 90 Degree Peel Tester

Large Size of 90 Degree Peel Tester

Force Control Cable with Signal Output Box

Force Control Cable with Signal Output Box

Manual Test Stand with Displacement Output Option

Manual Test Stand with Displacement Output Option

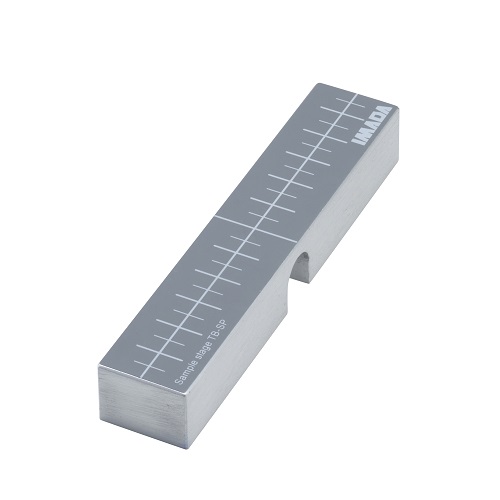

Cutting Base Plate with groove and knife edge probe

Cutting Base Plate with groove and knife edge probe

Upper attachment for 4-point bending test

Upper attachment for 4-point bending test

Main shaft stopper with a butterfly screw for MTS series

Main shaft stopper with a butterfly screw for MTS series

Wide Rubber Roller for Peel Test

Wide Rubber Roller for Peel Test

Motorized Rubber Roller for Peel Test

Motorized Rubber Roller for Peel Test

Peel Fixture for Packaged Cooked Rice Lid

Peel Fixture for Packaged Cooked Rice Lid

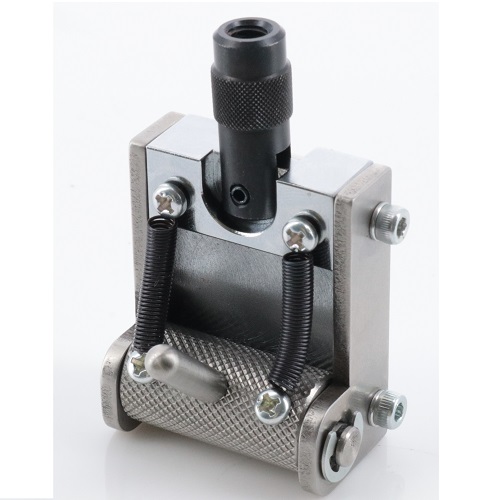

Cam grip with spring

Cam grip with spring

Wedge Grip Without Adaptor

Wedge Grip Without Adaptor

Customized Peeling Tester

Customized Peeling Tester

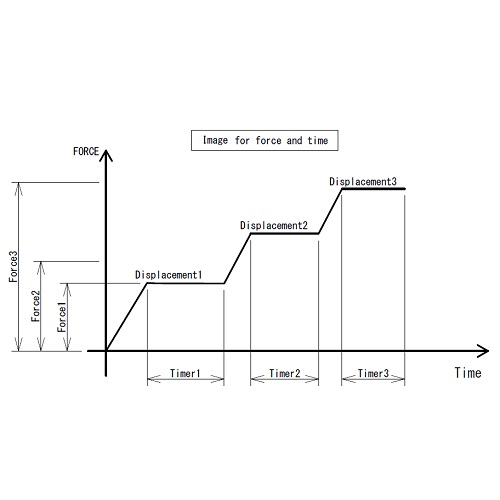

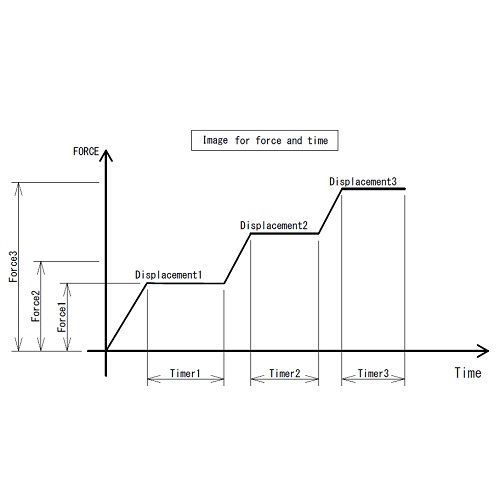

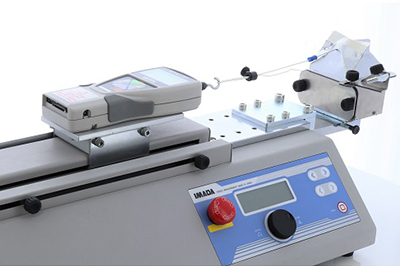

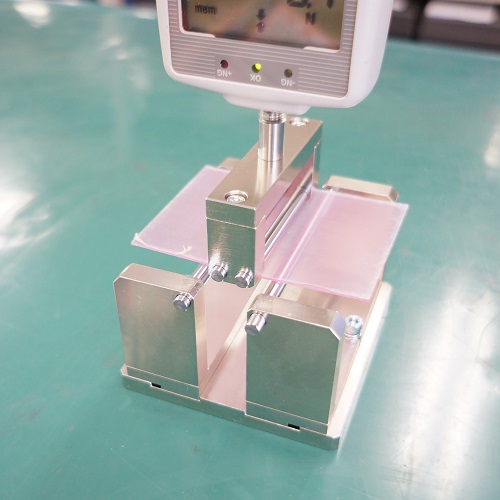

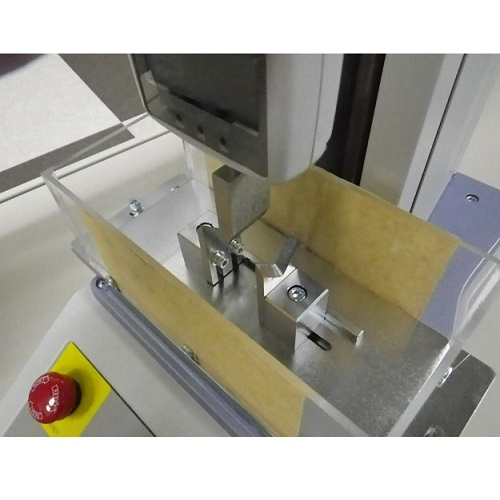

Test Stand with 3-stage Force/Displacement setting/holding function

Test Stand with 3-stage Force/Displacement setting/holding function

Torque Stand Shaft for Child Proof Lock Measurement

Torque Stand Shaft for Child Proof Lock Measurement

90 degree Peel Test Jig (High Capacity Type)

90 degree Peel Test Jig (High Capacity Type)

Tabletop Force Gauge Calibration Unit (High Capacity Type)

Tabletop Force Gauge Calibration Unit (High Capacity Type)

One-touch toggle clamp for Coefficient of Friction Fixture

One-touch toggle clamp for Coefficient of Friction Fixture

Compact Motorized Test Stand

Compact Motorized Test Stand

Tube Fixing Jig

Tube Fixing Jig

Visualized Film Chuck

Visualized Film Chuck

Tensile and Compression Torque Tester

Tensile and Compression Torque Tester

Standards-Compliant Measurement

Standards-Compliant Measurement

ISO 14704: 2000 Fine Ceramics 4-Point Bend Tester

ISO 14704: 2000 Fine Ceramics 4-Point Bend Tester

Ampoule 3-Point Bend Tester

Ampoule 3-Point Bend Tester

ISO/IEC 10373-1: 2006 Peel Tester of Identification Card

ISO/IEC 10373-1: 2006 Peel Tester of Identification Card

ISO 17480: 2015 Peel Tester for Gable-Top Package

ISO 17480: 2015 Peel Tester for Gable-Top Package

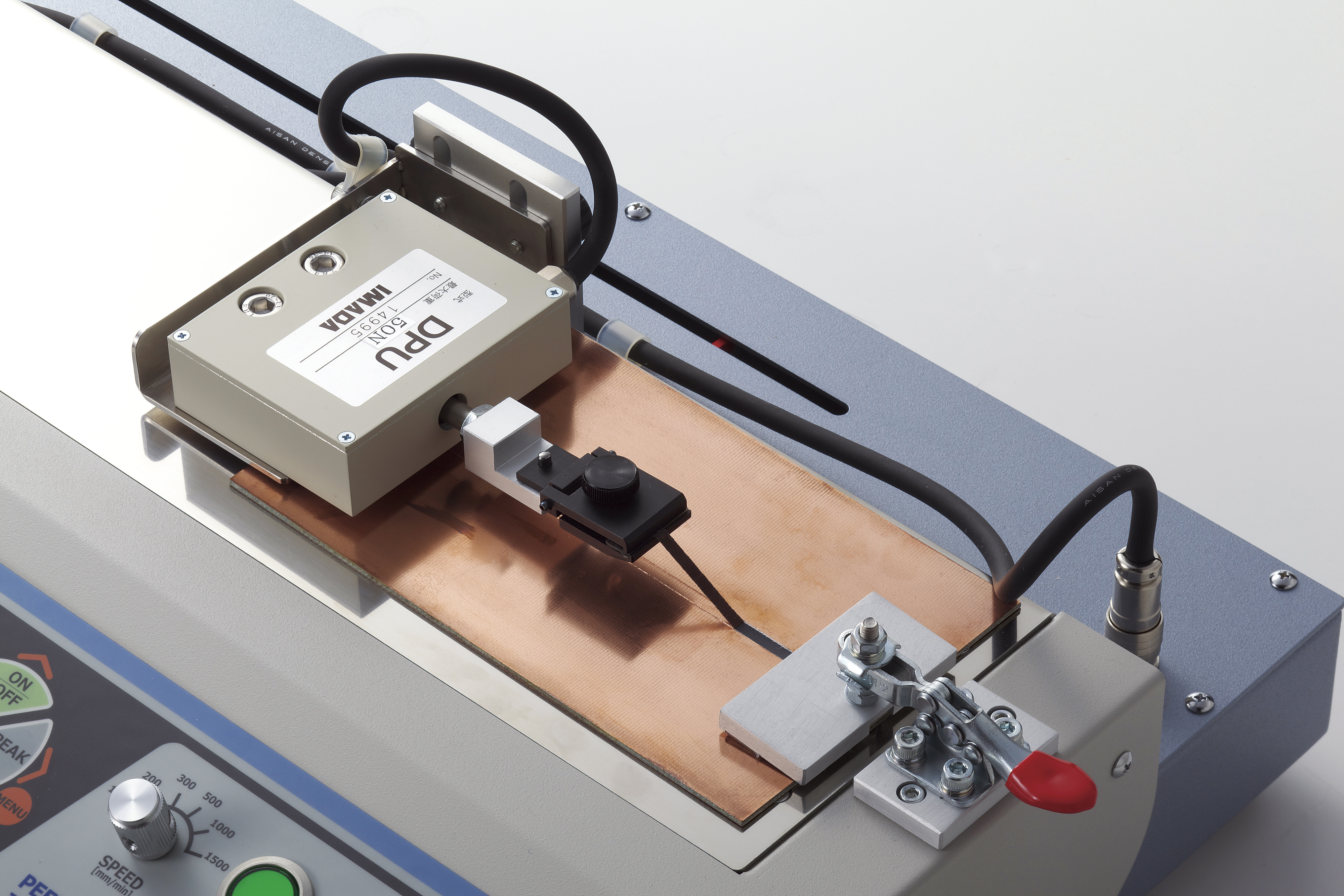

ASTM D1894: 2014 Coefficient of Friction (COF) Tester

ASTM D1894: 2014 Coefficient of Friction (COF) Tester

Attachments for score bend test

Attachments for score bend test

ISO 17480: 2015 45 Degree Complete Peel Test Fixture for Container Lid

ISO 17480: 2015 45 Degree Complete Peel Test Fixture for Container Lid

IEC 61010-1 (2010) Spherical Jig for Compression Testing

IEC 61010-1 (2010) Spherical Jig for Compression Testing

ASTM D4032(Withdrawn 2025)Standard Test Attachment for Fabric Stiffness by Circular Bend Procedure

ASTM D4032(Withdrawn 2025)Standard Test Attachment for Fabric Stiffness by Circular Bend Procedure

Peel Test Jig for Gable-Topped Package (No sample cut type)

Peel Test Jig for Gable-Topped Package (No sample cut type)