Product Search

Solution Search

Searchable by product name, product model or standard.

*To search by solution, switch to “solution search.”

i.e., Load Cells, ZTA-50N, 7864 (for ISO 7864)

Searchable by you force type, industry, standard or product sample.

*To search by product, switch to “product search.”

i.e., Compression, 7864 (for ISO 7864)

SEARCH

PRODUCTS

Force Gauges

Force Gauge Overview & How to Use

Force gauges, also known as "push-pull gauge" or "push-pull scale" are measuring equipment that measures the load (force) acting on a sample. They can measure tension, compression, bending, shear, as well as peel, adhesion, and friction. They are popular in manufacturing and play critical role in quality control and R&D, such as evaluation of mechanical properties of materials (strength, hardness, toughness, or durability), verification of safety and operability of parts and products, and compliance with industry standards.

Digital Force Gauges

Digital force gauges are with built-in load cells and used to measure compression, tension, peel, or coefficient of friction.

Digital force gauges feature data management on a PC and detailed analysis based on the data. Convenient functions such as pass/fail test, measurement time management, and memory are included. Some models can expand function by downloading optional software from IMADA-Connected.com.

We started manufacturing digital force gauges in 1986. With extensive know-how, we accommodate various measurement needs, from simple peak acquisition to those that can be used to create highly accurate graphs for force change analysis. For details, refer to the product list below.

For spring-loaded mechanical force gauges, click here → Mechanical force gauge

Mechanical Force Gauges (Push Pull Gauges)

Mechanical force gauges, also known as "push-pull gauges" or ""push-pull scale, are analog force measuring device for spring mechanism and are used to measure push and pull forces.

Mechanical force gauges are easy to read the transition of force by the movement of the needle and can realize stable force loading. The robust construction and the power-source free makes them easy to store and manage, and that is the primary reason why mechanical force gauges are popular in many quality control sites. If your usage is limited, mechanical is recommended for its low-cost and easy storage.

IMADA mechanical force gauges are signature product and have been supporting manufacturing since 1947. See the details from the product list.

*Due to their spring-loaded structure, mechanical force gauges are not suitable for impact tests such as destructive tests. Digital force gauges are recommendable for such tests.

Other Force Gauges

Muscle Force Measurement Device is a set of attachments for measuring workload and muscle strength, and can be used in safety force management and in situations where the action of human power is to be verified.

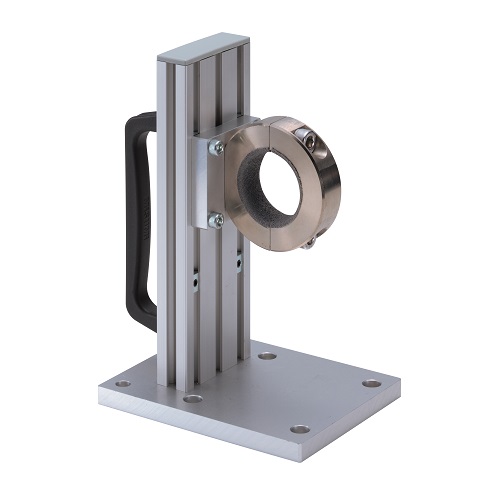

Tabletop Force Gauge Calibration Unit

Tabletop calibration unit for checking the accuracy of force gauges. It allows for easy daily inspection and in-house calibration of force gauges with handle operation.

Click here for our calibration service.

Load Cells (Force Sensors)

Load Cell Overview & How to Use

Load Cells, also known as "Load Transducers" or "Load Sensors" are sensor that detects force or torque and converts its magnitude into an electrical signal.

They come in various shapes, such as beam, coin, or S-shape, and can be used for measurement in small spaces or built into specific equipment. There are also particular types with shapes suitable for unique samples such as vehicle handbrakes and footbrakes. Some can be used even in harsh environments such as high/low temperatures, high dust, or exposure to water.

Compression and Tension (Bi-directional) Load Cells

Compression and tension dual-purpose load cell can be used for both compression and tension. We offer various load cells, including rectangular type that is ideal for installation in equipment, pen-type that can measure in narrow gaps, and waterproof type.

Load cells for compression single-purpose and tension direction single-purpose are also available.

Compression load cells>

Tension load cells >

Compression Load Cells

Space is often limited when using compression load cells, thus they are designed to be compact. We offer variety, i.e., waterproof or wide temperature range types.

For details, check the list at the bottom.

Dual-use type for both compression and tension are also available.

Compression/Tension Load Cells >

Tension Load Cells

Tension load cell is designed to measure tension effortlessly. Check the details below.

Dedicated Load Cells

Dedicated load cell is for specific measurements, such as for automobile and motorcycle brakes, or automatic doors.

They feature secure and easy fixation and workability.

Torque Load Cells

Torque load cell measures turning or twisting force by hand-holding and rotating the sensor.

Various attachments can be fixed to the tip of the torque load cell to suit the samples. A flange that can be fixed to a jig or equipment, is also available.

Only eZT and eFA Plus models (sensor interchangeable type) are available for these torque road cell indicators.

Force Test Stands

Force Test Stand Overview

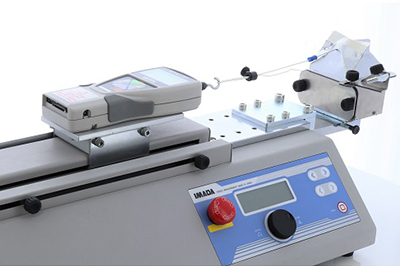

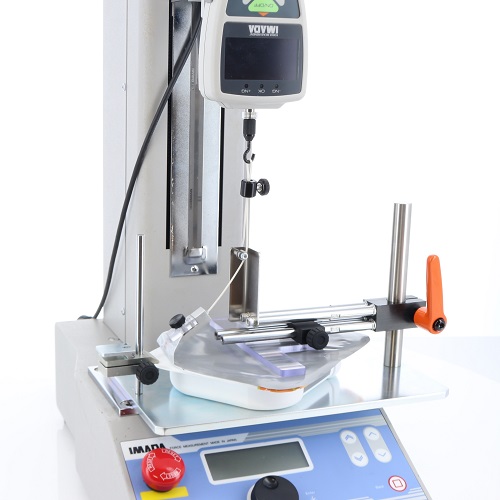

Test stands are supplementary products for force measurement to move a force gauge either vertically or horizontally.

Combined with a force gauge and attachments, they can be used as simple desktop force tester for more precise measurement. Unlike handheld measurement, they push and pull the force gauge to make the test speed and direction uniform, thus materializing highly repeatable measurement.

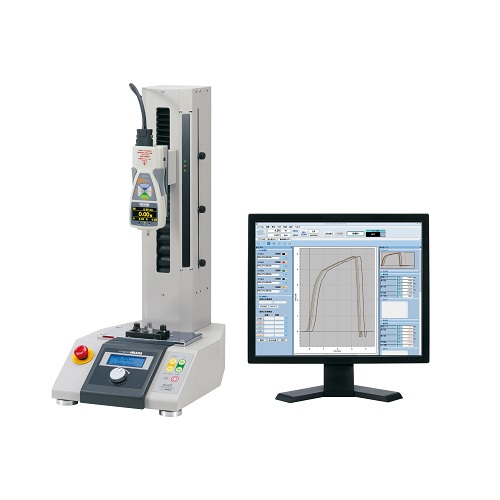

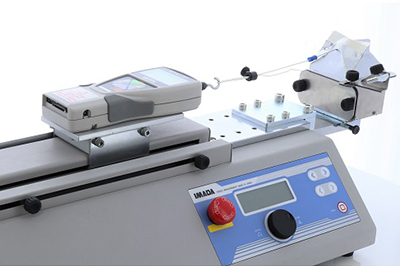

Motorized Test Stands

Combined with a force gauge and attachments, motorized test stands can be used as a simple force tester. By equalizing the direction of movement and speed, the measurement repeatability can be improved compared to the use of a force gauge alone. Easy measurement with a switch operation also reduces labor amount, especially when measuring large forces.

Standard type can be interlocked with a force gauge via a dedicated cable to control a specific time, force, and frequency.

Manual Test Stands

Combined with a force gauge, manual test stand can be used as a simple force tester. By making the direction of movement uniform, the repeatability can be improved compared to the use of a force gauge alone.

The facts that it is power-source and small in size make it ideal for the use on a workbench or any other places. Price is another feature.

Check the list for more information.

Force-Displacement Measurement Unit / Force-Deformation Evaluation Unit

The measurement unit for Force-Displacement relationship analysis (FSA series ) and force-deformation evaluation (FSA-Q series ). The relationships can be analyzed by measuring multiple elements simultaneously without selecting individual products.

Test Stand Accessories

Accessories for test stands to enhance measurement, such as interlock covers and safety shields for motorized test stands to prevent scattering of measurement objects, as well as mounting plates of attachments.

Torque Testers

Torque Tester Overview

Torque is the torsional moment (turning or twisting force) that acts on an object when it rotates, and the device that measures torque is Torque Tester. Torque testers can be used to measure opening and closing force, turning force, and sliding resistance, and indicate them in the unit of N-m, N-cm, kgf-m, kgf-cm, lbf-in, or ozf-in .

Torque measurement is popular, from the torsional strength of circuit boards, the tightening force of screws, the opening force of PET bottles and jars, and the operating force of rotary switches and keys, as a few examples.

Screw Cap Torque Testers

Screw Cap Torque Tester is the torque measuring instrument which measures the opening and closing torque of various container lids (screw caps) such as PET bottles and jars. It reads the turning force and displays a numerical value.

The table on which the measurement sample is fixed is available in a range of sizes, so it can measure not only the lid of a container, but also various other torques, such as the feed torque of lipstick or the operability of a volume switch.

For more precise torque measurement need, we offer a solution of automatically turning a measurement sample using a dedicated stand instead of handheld. Using a torque stand for torque measurement, especially in R&D, is highly recommendable, because the constant turning speed and accuracy improves the repeatability of measurement.

Click here to see the complete lineup.

List of all torque tester >.

Also check a collection of measurement examples.

Handheld Digital Torque Gauges

Handheld Digital Torque Gauge is used to measure torque by holding the sensor by hand. Measuring the torque to tighten screws or to turn rotary switches are the most familiar examples. Although often confused, torque wrenches and torque screwdrivers are tools for tightening screws at the appropriate torque value, whereas torque gauges are measuring equipment that quantify how much torque is actually applied. Torque gauges are measuring equipment used on sites of quality control and research and development to improve operability, strength, and comfort.

The sampling speed is as fast as 2000 Hz, so it accurately captures peak values and outputs smooth and highly useful data when graphing changes in torque values.

A jig (attachment) can be attached to the tip of the sensor. Selecting an attachment of the appropriate shape for the sample is important. Various attachment shapes are available to accommodate a range of samples. We offer custom-made attachments as well.

Click here to see the complete lineup.

Torque Gauge List

Click here to see an example of torque gauge measurement (video).

Built-in Torque Gauges

Built-in digital torque gauge is designed to integrate the sensor into torque testers or torque control systems in production line for torque measurement. It suits for measurements in limited space due to the small sensor.

Torque Tool Testers

Torque tool tester measures the torque (turning force) of electric screwdrivers and torque drivers. Torque can be easily measured by simply inserting the tool into the joint on the lower right side of the top of the torque meter and activating it, and the pass/fail results are clearly indicated by a lamp, making it simple and easy to use and ideal for daily inspections

Torque Test Stands

Torque Test Stand Overview

Torque stands are rotating equipment for torque testers. Combined with a torque tester and attachments, it can be used as a simple torque tester to achieve more precise measurements.

Unlike hand-held measurement, they can perform the rotation movement or fix the sample. This reduces shake of manual operation and equalizes the test speed, consequently delivering highly repeatable measurements. Rotating the test object more than 360 degrees or continuous rotating can be easily conducted.

Motorized Torque Test Stands

This is a measurement assistive equipment for attaching screw cap torque tester (DTXS and DTXA series) and automatically rotating the sample. Rotating the sample at a constant speed enables more repeatable measurement than when measuring with a handheld torque gauge alone. It is also ideal for repetitive endurance tests that are difficult to perform manually.

Manual Torque Test Stands

This is an assistive stand used with a torque gauge for more stable or continuous turning.

Torque-Angle Measurement Unit

Torque-angle measurement unit can measure torque and angle simultaneously, graph and analyze the correlation between torque and angle. Torque-angle measurement is used in various situations, i.e., to measure the repulsive force of materials twisted at a certain angle, or to evaluate the operability of a rotating switch based on the correlation between torque and angle.

We offer two types: 1) a handheld that measures by twisting the sensor by hand, and 2) a desktop that can automatically rotate at a digitally set speed.

Attachments, Grips & Fixtures

Attachment, Grip & Fixture Overview

An attachment is a jig that is attached to a test stand or a test stand of a force gauge. Since it is the part of the attachment that actually contacts the sample to be measured, the attachment is a very important element in force measurement.

A force gauge can be used to measure compression force by attaching an attachment for compression test, and can measure tension force by replacing it with an attachment for tension test. In other words, a force gauge can read a force value, but the type of force to be measured is determined by the attachment, not by the force gauge.

Accessory Attachments

Accessory attachments that are included with the purchase of a force gauge (type and material of attachments vary depending on the model of force gauge). They can also be ordered individually.

Compression Attachments

An attachment for compression test is a jig for measuring pressing force (compressive strength). Combined with a force gauge, a compression test jig can be used as a measuring equipment for easy hand-held compression test. Or, by combining a force gauge and a test stand, it can be used as a desktop compression tester.

There are various types of compression tests, such as pressing the entire sample, strength test by pressing one point, bending test, and sticking test. To accommodate such a wide variety of compression test methods and samples, we offer an extensive lineup of compression test jigs.

Inform us the purpose of the test and the sample to be measured, and we will assist you in the selection of the right jig. We also offer custom-made compression test fixtures with larger or smaller dimensions, special shapes, and so on. Contact us for more information.

For details, see the list at the bottom.

Check a video of compression test measurement examples >>

Tension Attachments

A Tension Test attachment is a jig for measuring pulling force. Combined with a force gauge, a tension test attachment can be used as a hand-held measuring equipment for simple tension test. Or, by combining a force gauge and a test stand, it can be used as a desktop tension tester.

A key factor in tension test is the appropriateness of the fixture. Tension test is a broad spectrum of testing methods, including tension fracture strength test, tear test, and peel test, and the samples subjected to tension test are also diverse. Therefore, it is important to select and use the most appropriate jig for the purpose, test method, and sample to be measured.

We offer a wide variety of tension test jigs to accommodate a wide range of tension tests and samples. Inform us the purpose of the test and the sample to be measured, and we will assist you in the selection of the right fixture. We also offer custom-made tension test fixtures with larger or smaller dimensions, special shapes, and so on. Contact us for more information.

For details, check the following list.

Click here to see an example of tension force measurement (video)

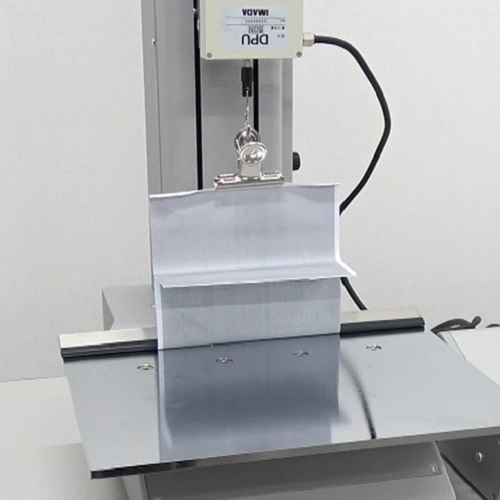

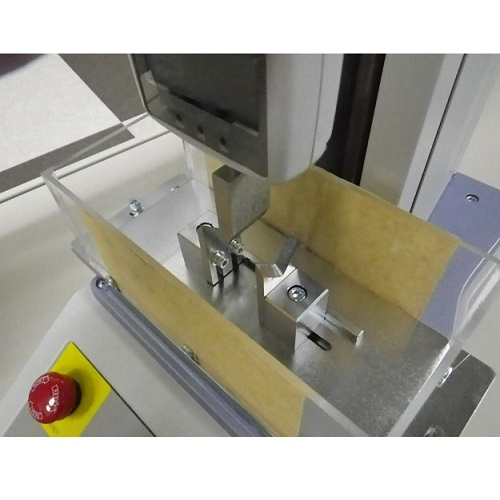

Peel Test Fixture

A peel test fixture is a jig for measuring peeling force and adhesive strength. It can be used as a desktop peel tester by using it with an IMADA force gauge and a test stand.

In addition to peel test to confirm whether tapes and films have sufficient adhesive strength, the overall demand for peel test has been increasing recently due to the importance of easy peelability of tapes and films, and there are many standards such as JIS.

In order to meet such diversified demands for peel test, we offer the following lineup of peel test fixtures as standard products, and also have a lot of experience in custom-made products with different dimensions and angles. Contact us for details.

We also offer a peel tester dedicated for 180-degree peel test.180-degree peel test>

Refer to the video collection of peel test examples >>

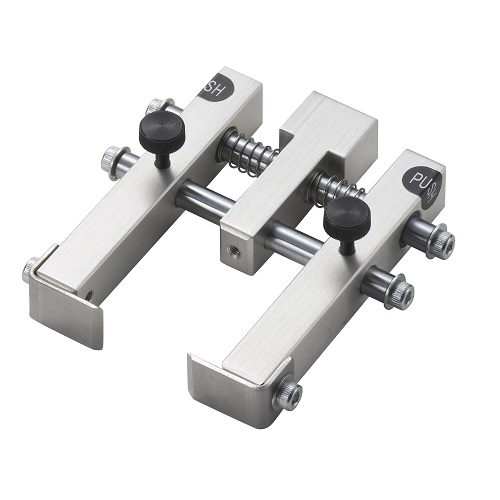

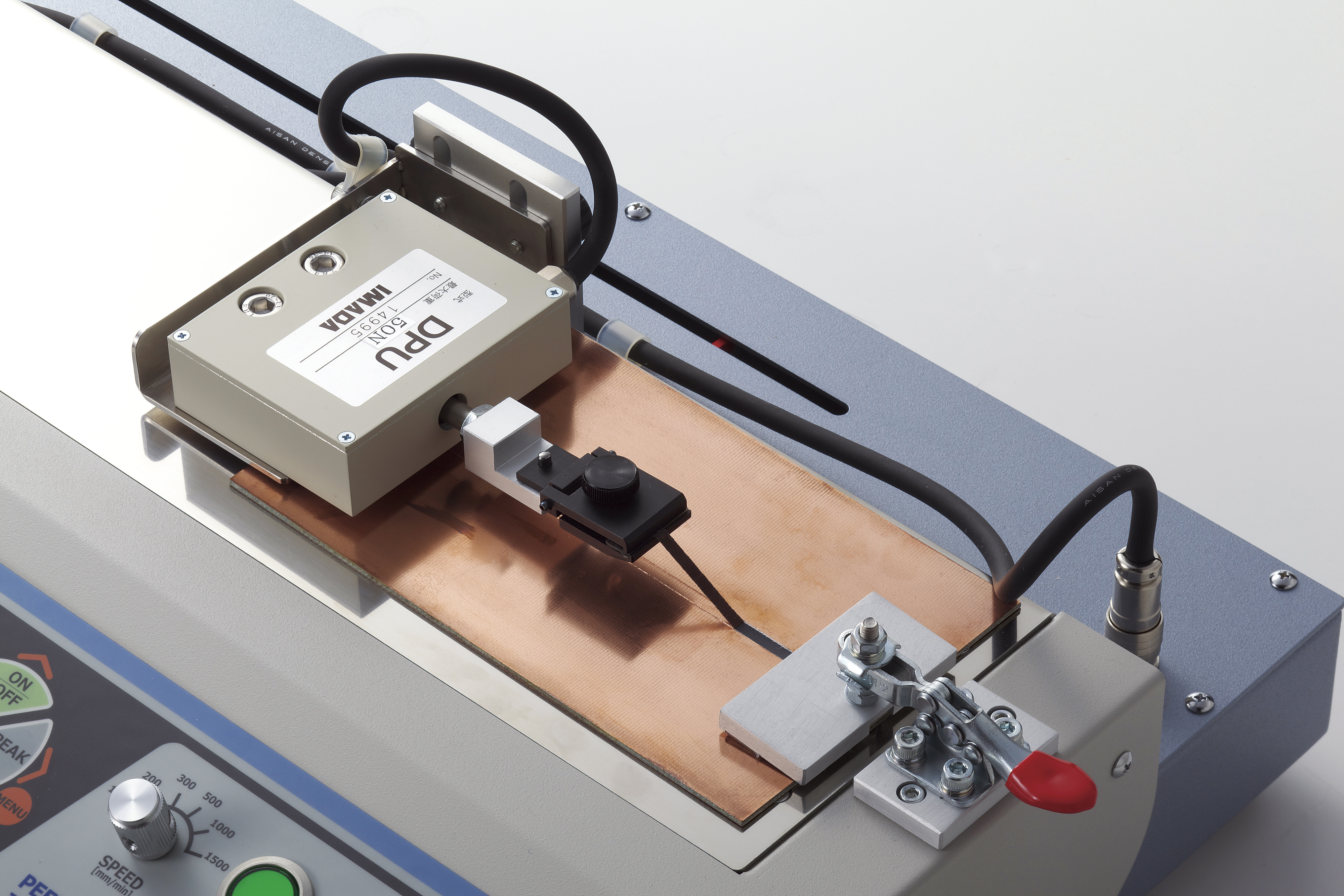

Friction Attachments

Friction measuring attachment is a jig for measuring the coefficient of dynamic and static friction of paper, or film. By using it with a force gauge and a test stand, it performs as a simple tabletop coefficient of friction tester. The included software draws the graph of the measurement results and calculates the coefficient of friction.

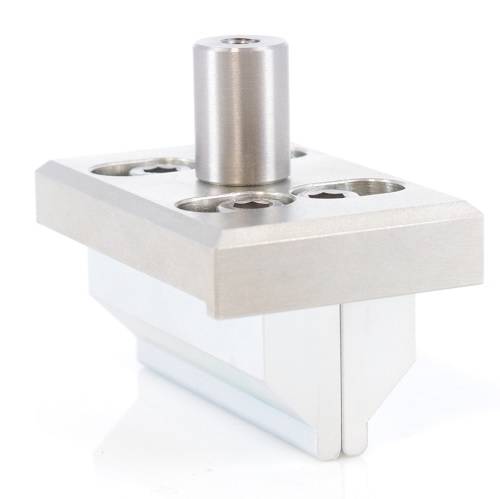

Compression and Tension Attachments

This is chuck jig that can be used for both compression and tension tests.

There are also jigs exclusively for compression test or tension test.

Attachment for Compression Test >>

Attachment for Tension Test>

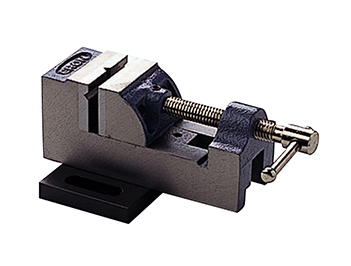

Vise Grips and Tables

These are force test jigs, such as vise grips that grab and hold the measurement object firmly and slide tables that allow easy centering of the measurement object. They are used by attaching them to a test stand.

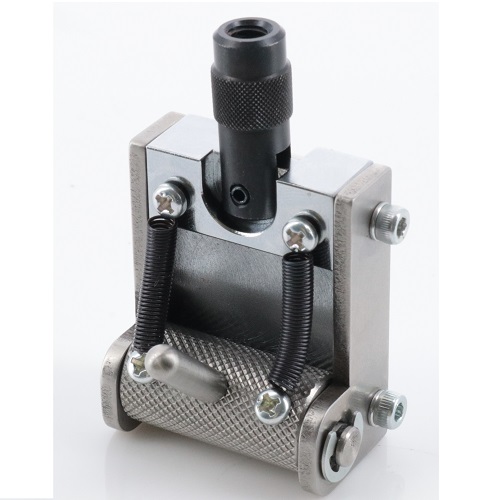

Wire Crimp Pull Test Attachment

Attachment for wire harness test is a jig for measuring the crimp strength of crimped terminals. Combined with a force gauge and a test stand, it can be used as a desktop crimp strength tester.

With the spread of EV (electric vehicles), the size of the wire harness market continues to expand. Quality control in the automotive industry is known be the most rigorous in the manufacturing industry, and an elevated level of quality is required for components. In response to this trend, the demand for crimp terminal strength measurement is also on the rise.

Since crimped terminals come in various shapes and sizes, we offer an extensive lineup of products to measure the crimp strength of a wide range of terminals, each of which is designed for efficient measurement.

For details, check the product list at the bottom. On each detailed page, you may find examples of jig and recommended product configurations, measurement examples (video), and more.

Automatic crimp strength measuring equipment are also available.

Auto Wire Harness Tester >"

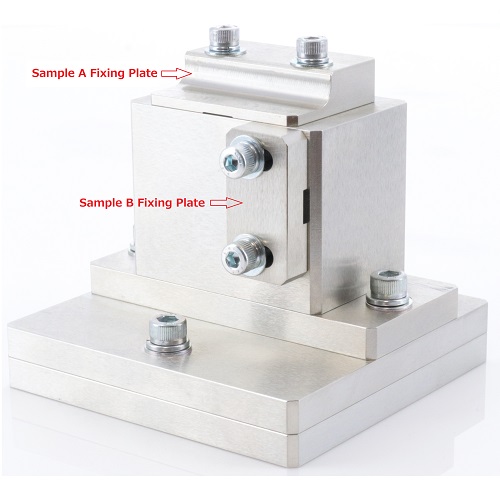

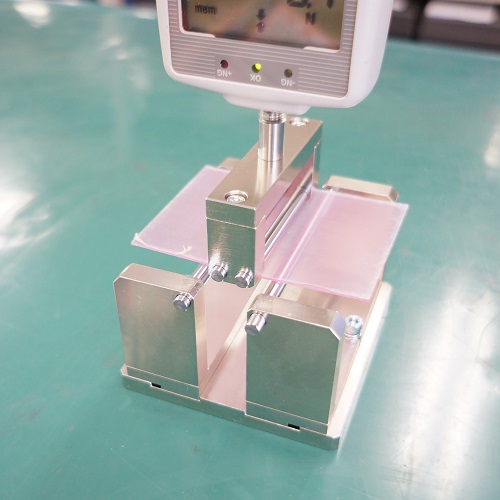

Chip Components Tension/Shear Test Attachment

Attachment for lead-free solder test is a jig to measure exclusively shear and peel strength of soldered/glued electronic components.

Recently, lead-free solder has been increasingly used to comply with RoHS and other directives. Furthermore, while components have become smaller and denser, they are also required to be more durable and reliable.

JIS standards related to lead-free solder testing have also appeared, and inquiries are increasing. The jigs introduced here are specially designed for lead-free solder tests that require delicate lead-free soldering such as QFP leads and chip components, and can also perform lead-free solder tests in accordance with related JIS standards.

Check the product, the details and view a video of a lead-free solder test.

Medical Attachments

Medical Device Attachments are force (strength) test jigs for quality evaluation of medical devices such as injection needles, vials, syringes, and so on. It can be attached to IMADA force gauge/test stand and used as a desktop force (strength) tester.

Because medical devices are required to have high safety standards in society, their quality control is particularly strict compared to other industries. JIS, ISO, ASTM, and others set various standards, and IMADA offers a wide range of strength test jigs that comply with such standards. Even if we do not have the standard-complied attachment in the product list, we can provide custom-made attachments in many cases, so contact us for details.

Check other force testing videos.

Example of strength test in medical equipment >

Pinching Force Test Attachment

Attachment for pinch force measurement is a jig to measure pinch force with tweezers, clips, clothespins, and so on. Use it in combination with a force gauge.

Torque Attachments

Torque Attachment is a jig attached to a torque gauge (torque meter) to measure torque such as rotational, twisting, and twisting forces. We offer an extensive lineup of attachments capable of gripping samples of various shapes, such as bottle and PET bottle lids, rotary switches, lipstick, and so on.

For details of each torque measurement attachment, see the list below.

Click here for the complete lineup.

List of all torque testers>

Click here to view torque tester measurement videos.

Food Texture Tester Attachments

Rheometer attachments is a jig exclusively for IMADA rheometer (food texture tester). A wide variety of jig shapes are available for various texture tests such as meat hardness, cheese consistency, pasta consistency, and rice chewiness. In addition, for hygienic reasons, they are made of resin, stainless steel, or other materials that are easy to clean.

If you don’t find the most suitable one, we will be happy to offer the custom-made custom attachments.

Click here for a collection of test cases in the food industry (video).

Optional Handles, Conversion Adapters & Other Accessories

These are additional accessories such as handles to be attached to a force gauge to apply stable force, adapters to allow attachment of different screw diameters, and so on.

Software / Download Card

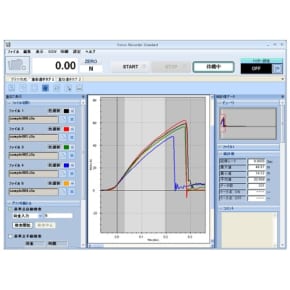

Software

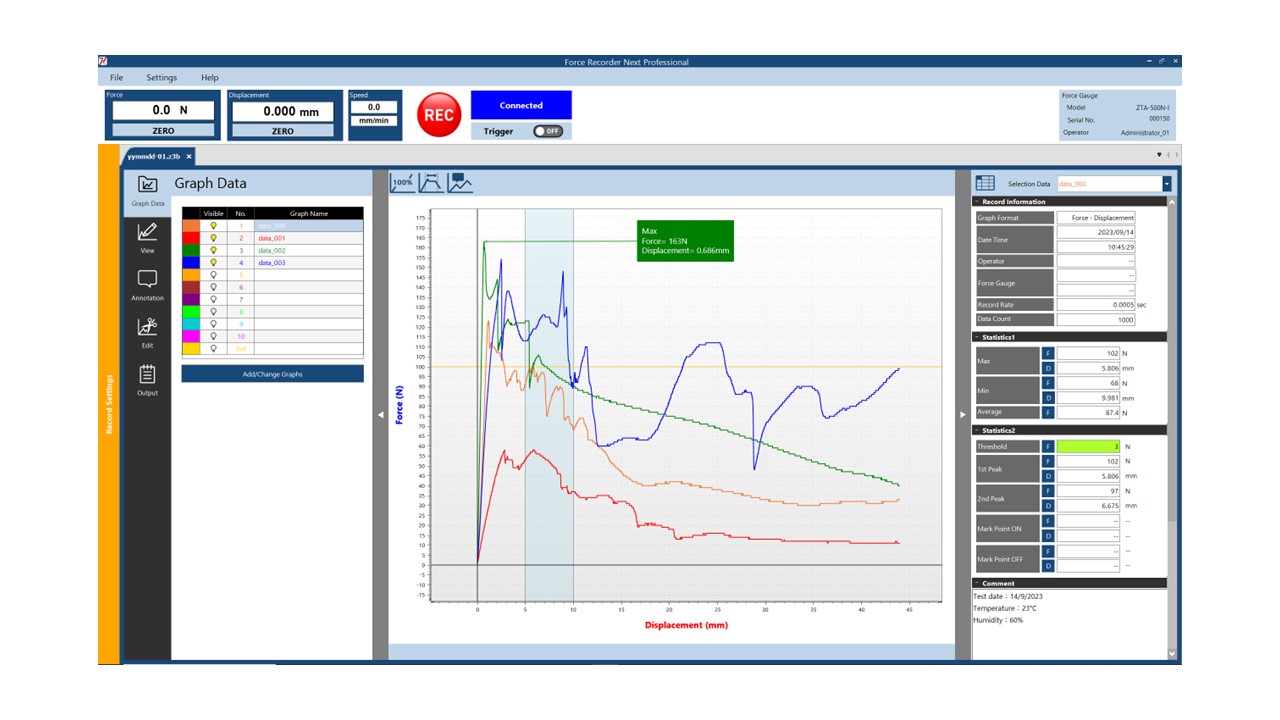

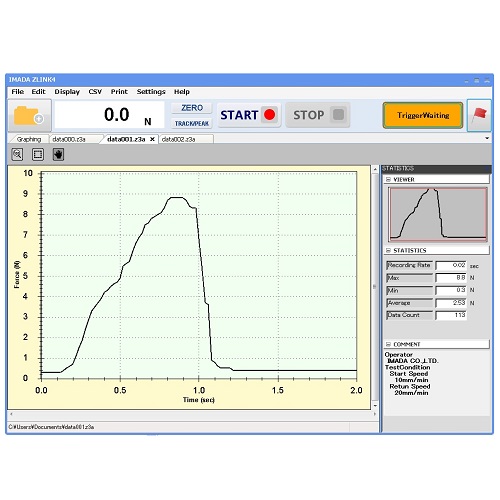

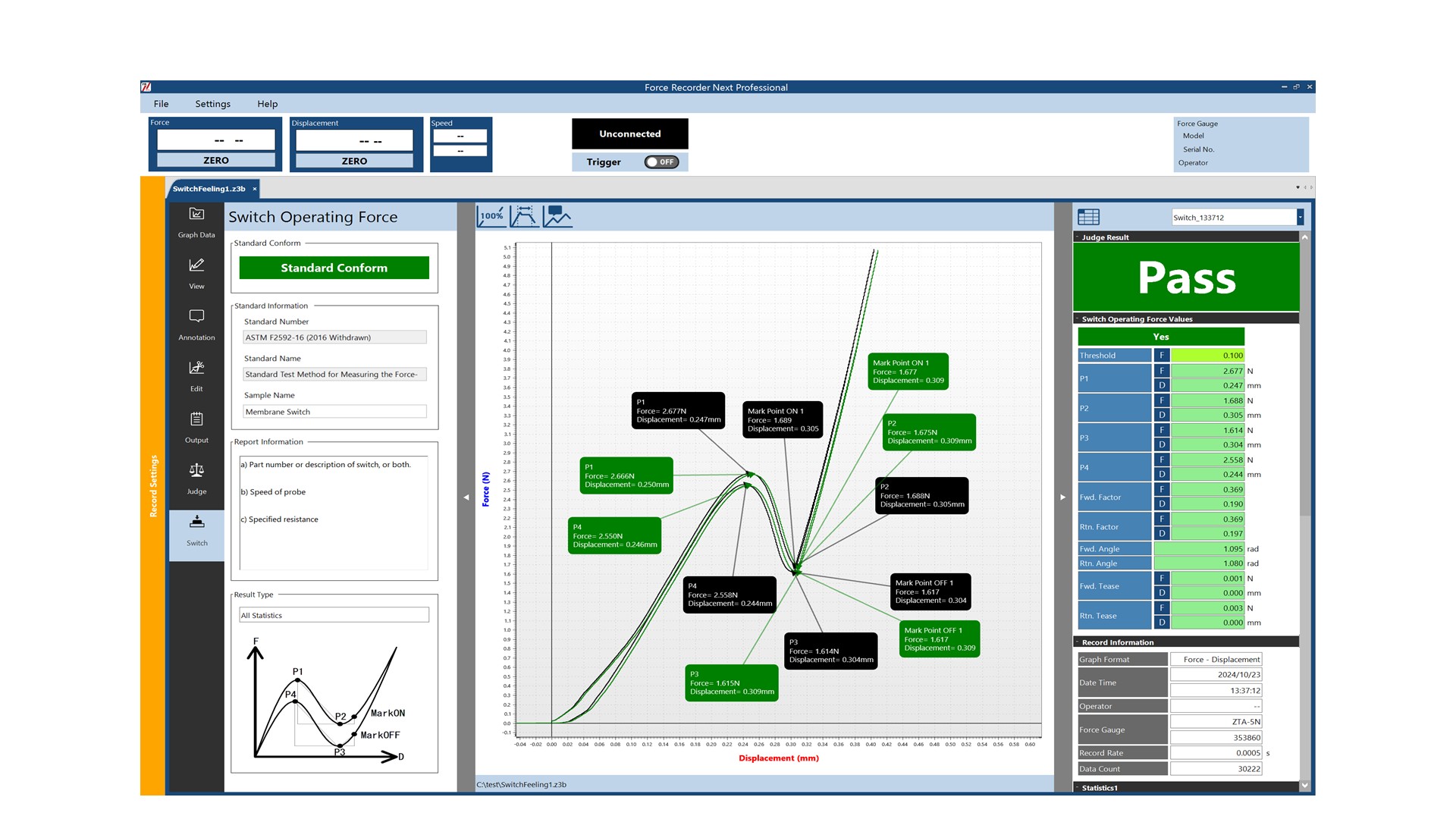

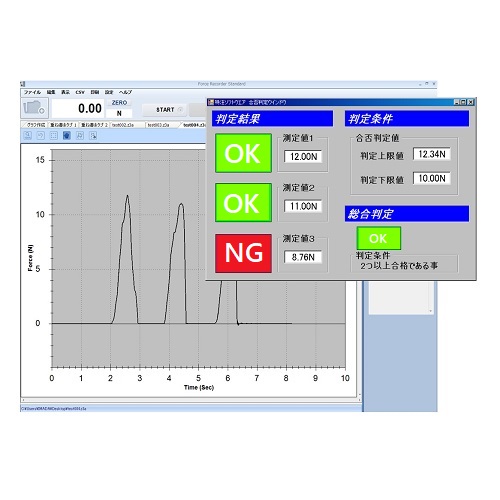

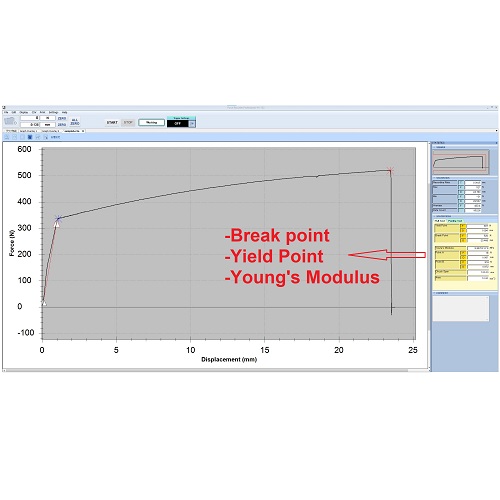

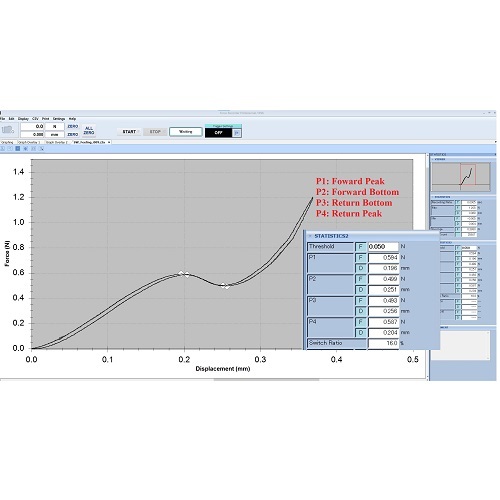

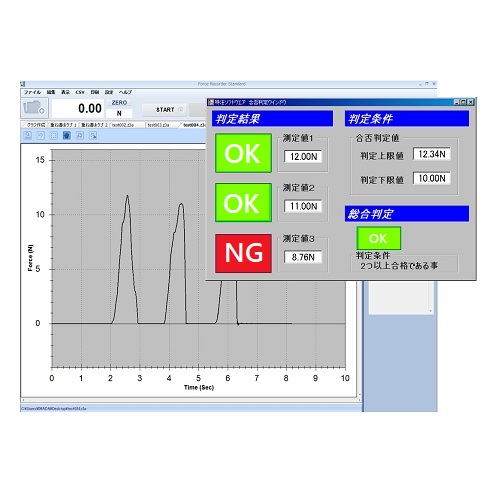

The software is designed to acquire and manage data from digital force gauges. The graphing software can draw force-time (torque-time) or force-displacement (torque-angle) graphs, allowing you to visually check the load transition and to evaluate whether there is an abnormality in the process of change in force as well as the maximum value.

Download Card

Download Card to download graphing softwares and chargeable additional functions from IMADA Connected.

Additional Chargeable Function for Software

The additonal chargeable functions for the graphing software Force Recorder Next series that can be downloaded from IMADA Connected. The required download card varies depending on the function.

180 Degree Peel Testers

Peel Tester for Embossed Carrier Tape's Cover Film

Peel Tester for Embossed Carrier Tape's Cover Film has capacity of 5N and measures the peel strength of cover tapes of embossed carrier tapes that contain semiconductors and electronic components in accordance with JIS and other industrial standards.

Next Series with firmware Ver. 5 or later offers improved measurement stability due to low noise, expandability with the ability to add functions on a dedicated website (IMADA-Connected.com), and the convenience of downloading various software and instruction manuals.

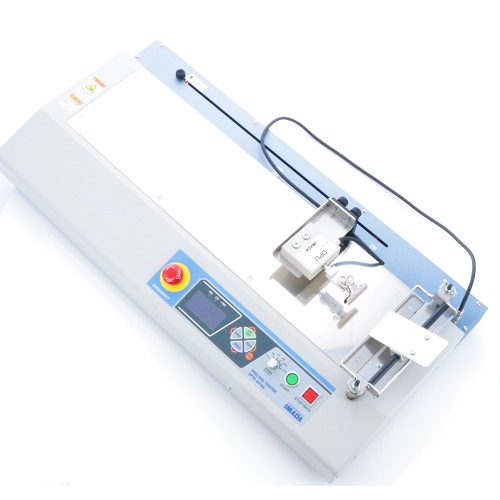

High Speed Peel Tester

Peel Tester is a specialized equipment for peel testing of numerous types of seals, adhesive tapes, and similar. The sampling speed is as fast as 2000 Hz, so that the peel strength can be quantified more precisely.

The dedicated software is included to graph peel strength and output the maximum, minimum, and average values (also including a field to input the tape width, so statistical values can be calculated for that specified width).

The moment the start button on the main unit of the peel tester is pressed to start measurement, the graph depiction starts automatically, and the data is saved, making it easy to save and analyze data.

The sample can be easily fixed for efficient testing. A broad range of peeling speeds are available, from 300 mm/min, which is often specified in JIS standards, to high-speed peeling tests up to 1500 mm/min.

With firmware 5.0 or higher, the peel tester can be expanded with additional functions and firmware updates online (ref, IMADA-connected.com).

For more information on each peel tester, see the list at the bottom.

Also refer to the peel tester case studies (videos).

Food Texture Analyzer & Related

Food Texture Analyzer (Rheometer)

Rheometer is a tester that quantifies the texture (mechanical properties such as hardness, elasticity, and adhesion) of food. Texture is a key factor in creating good taste, just as potato chips that are soggy do not taste good. Numerical control of texture, such as crispiness and stickiness, can stabilize the taste and quality of food products. Demand for texture test is increasing, and we recognize it as a sign that consumers are becoming more sensitive to texture.

Recently, with the aging of the population worldwide, increasing number of food products are being measured for texture and hardness from the perspective of whether they are easy to chew even for elderly people with weakened masticatory skills. As a result, industry standards for ease of chewing, such as "food for people with dysphagia" and "universal design food," have emerged.

IMADA rheometers (food texture testers) are programmed for easy measurement in accordance with these standards.

In addition to the rheometer, we also offer a simple unit to manually measure food hardness.

For details, see the product list at the bottom.

Click here for a collection of test cases in the food industry (video).

Food Hardness Testing Unit

This compact unit manually measures food hardness. The lever type is easy to operate and the stainless steel construction is easy to clean.

This is also recommended when there are only a few types of food samples or when it is sufficient to obtain the maximum, minimum, and average values.

Wire Crimp Pull Testers

Automatic Wire Crimp Pull Testers

All you have to do is press start button, then the tester automatically performs wire crimp pull test and saves data.

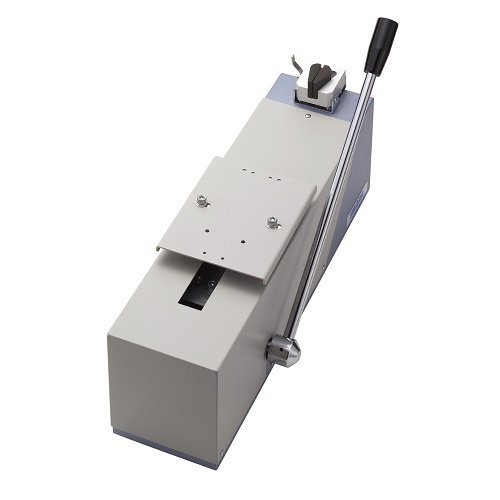

Manual Wire Crimp Pull Testers

This is a dedicated stand to measure the crimp strength of crimped terminals and is used in combination with a force gauge. The lever type provides high measurement efficiency and lower cost compared to auto harness testers. Measurable up to 500N.

Other Equipment

Displacement Sensors

Displacement and Angle sensors to be mounted on equipment. Using together with IMADA force gauge or torque gauge, they allow for easy force-displacement or torque-angle measurement.

Output Equipment

We offer a variety of equipment for outputting and managing data, including wireless units that enable efficient management of measured data.

Custom Made

Measurements in Special Environment

We offer measurements in environments where temperature, humidity, limited space, and other factors cannot be measured with standard measuring instruments.

Particular Samples Measurements

We provide consultation for measuring samples that are difficult to grip with standard attachments, such as slippery, deformable, or distorted shapes.

Resize & Modification

We propose modifications to the specifications of standard products to adapt them to the sample geometry, measurement conditions, and operating environment.

Additional Functions to Software

We offer software modifications to improve your data management methods and workability.

Safety Improvement

We offer equipment to prevent damage to the human body in the measurement of large forces and samples that are prone to scattering.

Integration to Equipment

We accommodate a structural or system specification change when integrating into a facility.

Measurement Efficiency and Productivity Improvement

We propose shortening measurement takt time, visualization of measurement line operation status, and so on.

Standards-Compliant Measurement

We offer measurement methods that comply with in-house standards and various industrial standards such as JIS, ISO, ASTM, and so on.

In-house Calibration

We propose jigs for easy daily inspections and / or in-house calibration facilities to perform periodic calibration.

Converter

Convenient Unit/Torque/

Tension conversion

6 Significant Digits (*Significant digits are meaningful digits that do not include zeros, which are used to indicate the scale.)

Products

HERE!

Attachments, Grips & Fixtures

Attachments, Grips & Fixtures

Custom Made

Custom Made

Measurements in Special Environment

Measurements in Special Environment

Temperature and Angle Adjustable Peel Tester

Temperature and Angle Adjustable Peel Tester

Spot Welding Pressure Gauge

Spot Welding Pressure Gauge

Attachment to Bend Sample 90 Degrees

Attachment to Bend Sample 90 Degrees

Horizontal Test Stand with Fine Adjustment Knob

Horizontal Test Stand with Fine Adjustment Knob

Tester With Thermostatic Chamber

Tester With Thermostatic Chamber

Tester With Far-infrared Heater

Tester With Far-infrared Heater

Table for Compression Load Cell

Table for Compression Load Cell

Test Stand for Testing at the Desired Position

Test Stand for Testing at the Desired Position

Particular Samples Measurements

Particular Samples Measurements

Peel Test Fixture for Crimped Postcard

Peel Test Fixture for Crimped Postcard

Attachment for Fixing Wide and Thin Materials

Attachment for Fixing Wide and Thin Materials

Attachment for Wine Cork Extraction Test

Attachment for Wine Cork Extraction Test

Attachments for 90 degree score bend test

Attachments for 90 degree score bend test

Attachments to measure forces to open flat pack carton

Attachments to measure forces to open flat pack carton

Attachments for break strength testing of lipsticks or lip balms

Attachments for break strength testing of lipsticks or lip balms

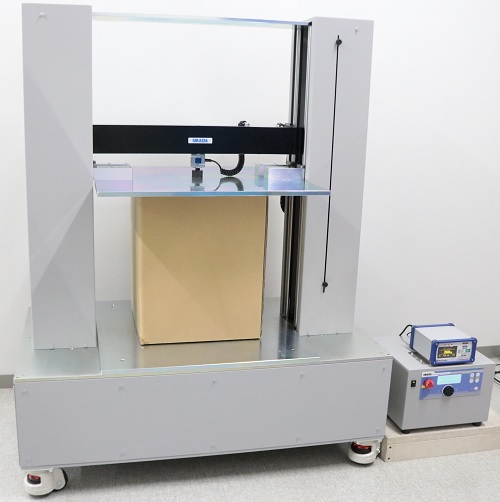

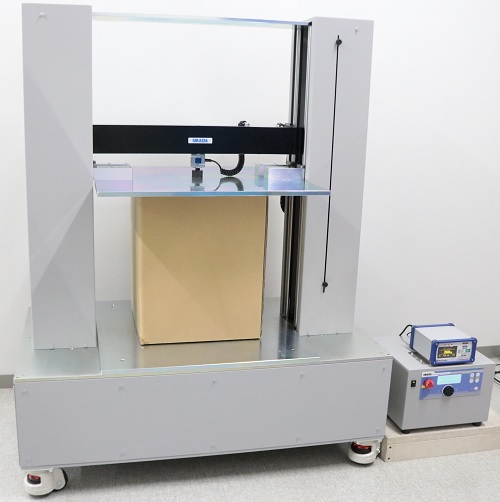

High capacity dual-column motorized test machine for compression test

High capacity dual-column motorized test machine for compression test

Film Grip with Openable Gripping Part

Film Grip with Openable Gripping Part

Pantograph Grip with Pressurization Mechanism

Pantograph Grip with Pressurization Mechanism

Motorcycle Accelerator Torque Test Fixture

Motorcycle Accelerator Torque Test Fixture

Peel Test Fixture for Solar Cell Ribbon

Peel Test Fixture for Solar Cell Ribbon

Test Stand With Large Table

Test Stand With Large Table

Compression Test Attachment for LCD Panel

Compression Test Attachment for LCD Panel

L-shaped Sample Fixture

L-shaped Sample Fixture

Attachment for Opening/Closing Force Test of Takeout Container Lid

Attachment for Opening/Closing Force Test of Takeout Container Lid

Attachment for Squeezing Force Test of Eye Drop Bottles

Attachment for Squeezing Force Test of Eye Drop Bottles

Compression Test Attachment for Squeeze Tube

Compression Test Attachment for Squeeze Tube

Attachment for Welded Nut Tension Test

Attachment for Welded Nut Tension Test

Attachment for Tube Tension Strength Test

Attachment for Tube Tension Strength Test

Attachment for Hard-to-Grip Samples

Attachment for Hard-to-Grip Samples

Attachment for Compression Test of Nasal Spray

Attachment for Compression Test of Nasal Spray

Individually Adjustable Torque Chuck Attachment

Individually Adjustable Torque Chuck Attachment

Resistance Force Measurement jig for Hair Combing Test

Resistance Force Measurement jig for Hair Combing Test

Attachment for Lateral Compression Test of Cup Containers

Attachment for Lateral Compression Test of Cup Containers

Water-Proof Shield for Motorized Torque Test Stand

Water-Proof Shield for Motorized Torque Test Stand

Biaxial Tension Tester

Biaxial Tension Tester

Resize & Modification

Resize & Modification

Press Test Fixture (Wide Size)

Press Test Fixture (Wide Size)

Remote Control Switch for Motorized Test Stand

Remote Control Switch for Motorized Test Stand

Semi-Customized Compression Attachments

Semi-Customized Compression Attachments

Large Size of Compression Tester

Large Size of Compression Tester

Large Size of 90 Degree Peel Tester

Large Size of 90 Degree Peel Tester

Force Control Cable with Signal Output Box

Force Control Cable with Signal Output Box

Manual Test Stand with Displacement Output Option

Manual Test Stand with Displacement Output Option

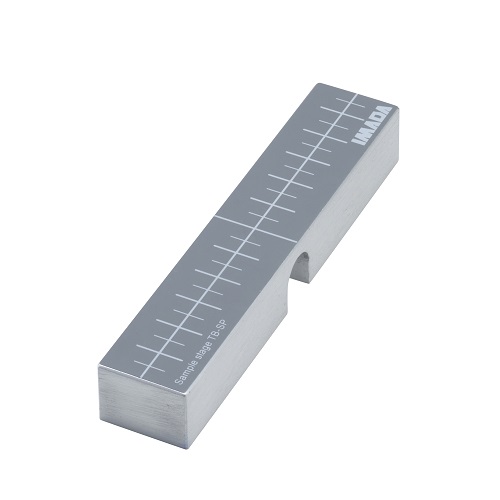

Cutting Base Plate with groove and knife edge probe

Cutting Base Plate with groove and knife edge probe

Upper attachment for 4-point bending test

Upper attachment for 4-point bending test

Main shaft stopper with a butterfly screw for MTS series

Main shaft stopper with a butterfly screw for MTS series

Wide Rubber Roller for Peel Test

Wide Rubber Roller for Peel Test

Motorized Rubber Roller for Peel Test

Motorized Rubber Roller for Peel Test

Peel Fixture for Packaged Cooked Rice Lid

Peel Fixture for Packaged Cooked Rice Lid

Cam grip with spring

Cam grip with spring

Wedge Grip Without Adaptor

Wedge Grip Without Adaptor

Customized Peeling Tester

Customized Peeling Tester

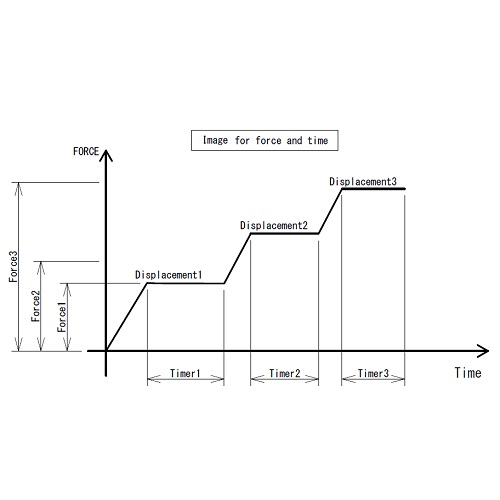

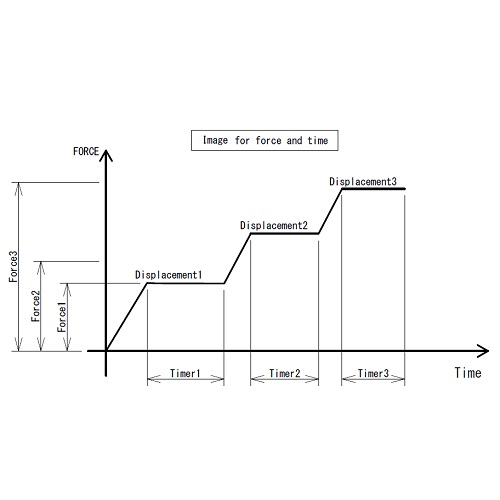

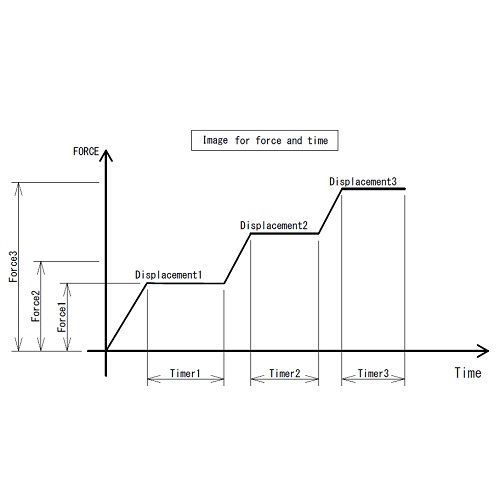

Test Stand with 3-stage Force/Displacement setting/holding function

Test Stand with 3-stage Force/Displacement setting/holding function

Torque Stand Shaft for Child Proof Lock Measurement

Torque Stand Shaft for Child Proof Lock Measurement

90 degree Peel Test Jig (High Capacity Type)

90 degree Peel Test Jig (High Capacity Type)

Tabletop Force Gauge Calibration Unit (High Capacity Type)

Tabletop Force Gauge Calibration Unit (High Capacity Type)

One-touch toggle clamp for Coefficient of Friction Fixture

One-touch toggle clamp for Coefficient of Friction Fixture

Compact Motorized Test Stand

Compact Motorized Test Stand

Tube Fixing Jig

Tube Fixing Jig

Visualized Film Chuck

Visualized Film Chuck

Standards-Compliant Measurement

Standards-Compliant Measurement

ISO 14704: 2000 Fine Ceramics 4-Point Bend Tester

ISO 14704: 2000 Fine Ceramics 4-Point Bend Tester

Ampoule 3-Point Bend Tester

Ampoule 3-Point Bend Tester

ISO/IEC 10373-1: 2006 Peel Tester of Identification Card

ISO/IEC 10373-1: 2006 Peel Tester of Identification Card

ISO 17480: 2015 Peel Tester for Gable-Top Package

ISO 17480: 2015 Peel Tester for Gable-Top Package

ASTM D1894: 2014 Coefficient of Friction (COF) Tester

ASTM D1894: 2014 Coefficient of Friction (COF) Tester

Attachments for score bend test

Attachments for score bend test

ISO 17480: 2015 45 Degree Complete Peel Test Fixture for Container Lid

ISO 17480: 2015 45 Degree Complete Peel Test Fixture for Container Lid

IEC 61010-1 (2010) Spherical Jig for Compression Testing

IEC 61010-1 (2010) Spherical Jig for Compression Testing

ASTM D4032(Withdrawn 2025)Standard Test Attachment for Fabric Stiffness by Circular Bend Procedure

ASTM D4032(Withdrawn 2025)Standard Test Attachment for Fabric Stiffness by Circular Bend Procedure

Peel Test Jig for Gable-Topped Package (No sample cut type)

Peel Test Jig for Gable-Topped Package (No sample cut type)